Menhir splitting machines

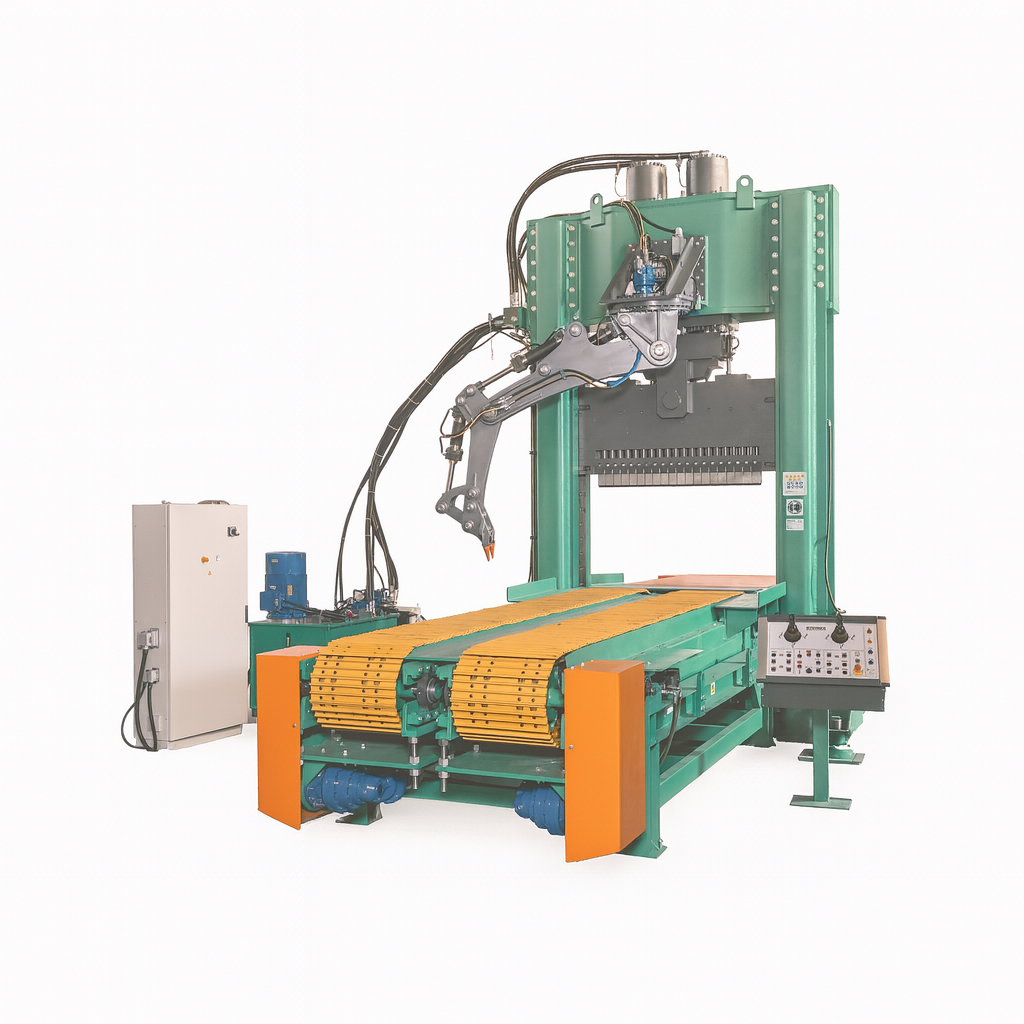

The splitting machines in the Menhir range are used primarily as primary machines in a plant configured for the production of semi-finished products in split stone or in the production of finished products such as large cordonades e wall stones. Menhir splitting machines are used to split granite, limestone, sandstone, slate, porphyry and many other types of natural stones monolithic.

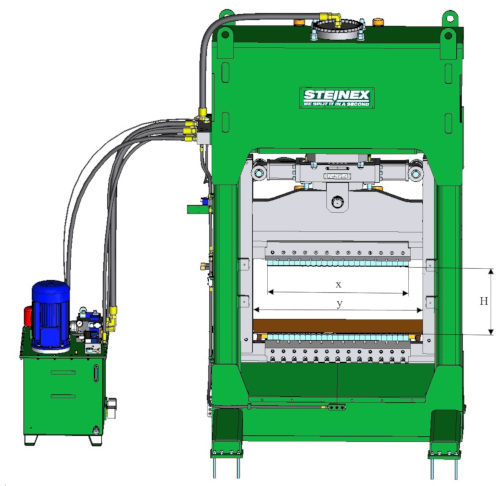

These robust splitting machines are used to split both raw material which sawn slabs. Unsawn stone includes stone blocks extracted from the quarry or very irregular natural stone extracted from the quarry with explosives. They are equipped with blades with a high adaptation and are designed with a tilting upper blade so as to make efficient splitting of irregular material, obtaining high quality in the split surface and reducing to the minimum the gap. Each machine is equipped with a highly efficient silenced hydraulic unit. The hydraulic unit has several pump configuration options, including the ability to adjust the speed at which the blade begins to apply pressure to the stone i.e., the eventual "ramp" or pressure plane of successive splits. Being able to set these splitting parameters allows our customers to optimize quality Of the split based on the properties of their material.

Menhir splitting machines come with a wide range of options including belts Conveyors, loaders, manipulators, remote control consoles e different hydraulic configurations Depending on the customer's needs.

SAWN SLABS, STONE BLOCKS, CREASED AND SEMI-PROCESSED

MAIN FEATURES

- Sturdy electro-welded and milled structure, fixed/mobile

- Silenced hydraulic power unit

- Blades with adaptation

- Ability to adjust the speed at which the blade begins to apply splitting pressure

STRENGTHS.

- Intuitive and easy to use

- Highly productive and durable

- Allows splitting of both rough and sawn stones with different sizes

- Minimizes waste

- Suitable for constant and intensive use associated with the splitting of hard stones

- Weight

- Reduced hydraulic oil consumption (e.g., 350 liters for 11 kW power pack)

Menhir Line - Sherpa 1000×600

Switzerland 1989 - 2000

Stone: sandstone

Menhir Line - Sherpa 1000×800

Switzerland 1989 - 2000

Stone: sandstone

Menhir Line - Sherpa 1000×800 320 Ton

Germany 1998 - 2008

Stone: dolomite

Menhir Line - Sherpa 1000×1100 640 Ton

Germany 1998 - 2008 Stone: dolomite

Menhir Line - Sherpa 1000×600 220 Ton

Italy 1999

Stone: lava stone Vesuvius and Etna

Menhir CM Line - Sherpa 1000×1100 640 ton

Italy 2000

Stone: Sardinian granite

Menhir Line - Sherpa 1300×600

Germany 2010

Stone: limestone

Menhir Line - Sherpa 1600×1000 440 ton

USA 2017

Stone: granite

Menhir Line - Sherpa 1300×600

Slovenia 2019

Stone: granite